Difference Between Cast Iron and Steel – Which Is Better?

Choosing the right materials is important in both manufacturing and construction. It covers issues such as durability, cost, and suitability for specific applications. The two most common materials are cast iron and steel. Understanding the difference between cast iron and steel is essential to making the right choices.

In this blog, we will go into more detail on cast iron vs. steel and steel vs. cast iron arguments. We will examine what makes each material unique and discuss circumstances in which they may be desirable. Whether you are just learning about these materials or need a quick remodel, this guide will clarify the cast iron and steel difference.

1 Historical Background

The difference between cast iron and steel begins with their historic development. Cast iron has been in use for a very long time. It became first popular in China around 5,000 years in the past and later in Europe. People liked it because it could be formed into many various things, like pots and pans, cannons, and components for bridges and homes.

Steel also has a long history but became much more common in the 1800s with a new way of making it called the Bessemer process. This method made steel cheaper and faster to produce. Today, steel is valued for its strength and is used a lot in building things like skyscrapers and bridges.

Both materials have changed over time. By knowing their history, we can see the cast iron vs steel differences and why each is important for different kinds of jobs.

2 Production Process

Cast Iron

The manufacture of cast iron includes pig iron and large quantities of scrap iron and limestone. The mixture is melted at a very high temperature in a blast furnace. The mixture is melted at a very high temperature in a blast furnace. Once the iron is melted, it is poured into moulds in various shapes. Cast iron cools faster and takes on the shape of the mould, which is great for making complex designs. This rapid cooling also makes molten steel very strong, but it can be brittle and break under high pressure.

Cast Steel

Steel production is a bit different and extra delicate. It starts by melting iron however at even higher temperatures. Steel-makers add much less carbon than used in cast iron, which makes steel tougher and less brittle. After melting, steel is often poured into moulds, however, it goes through additional steps like forging or rolling, which makes it stronger. These extra steps make steel extra durable and flexible than cast iron.

The main difference between cast iron and steel in production is the amount of carbon and the post-melting processes. Steel’s additional treatments give it higher strength and flexibility, which is why it’s preferred for structures needing to withstand a lot of weight or force.

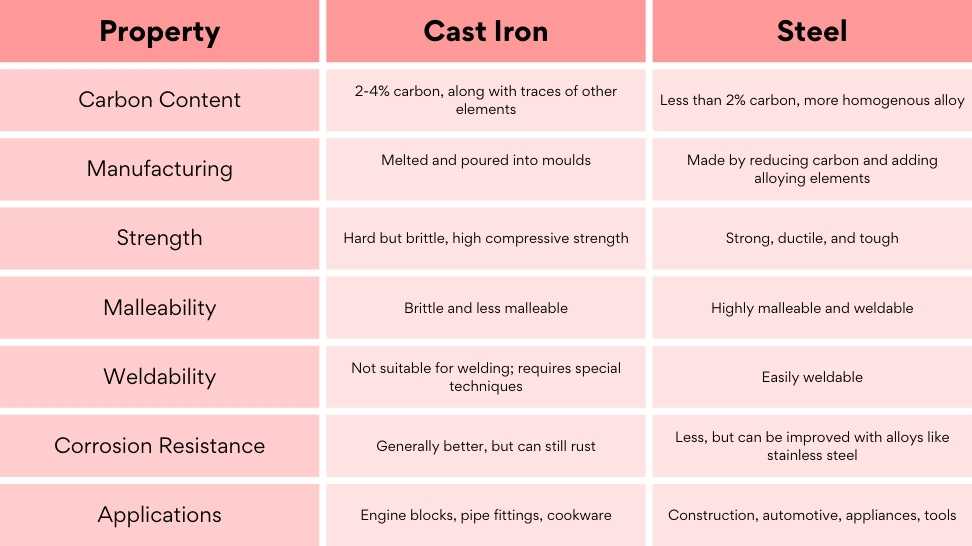

3 Physical Properties

When we talk about the cast iron and steel difference, it’s important to look at their physical properties like density and melting point.

Density

Cast iron is generally denser than cast steel. This means that cast iron is heavier for the same volume compared to cast steel. This higher density makes cast iron strong under compression, but it can be more brittle and likely to crack under stress.

Melting Point

Cast iron has a lower melting point than cast steel. This means it can be melted and moulded at lower temperatures, making it somewhat easier to work with for casting into complex shapes. Steel’s higher melting point requires more intense heat to mould and shape, which can make the manufacturing process more energy-intensive.

Other Properties

Besides density and melting points, there are other differences too:

- Strength and Toughness: Steel is generally stronger and more durable than cast iron. It can handle more stress and strain without breaking.

- Corrosion Resistance: Cast iron is more resistant to corrosion from weather and chemicals than plain carbon steel, but there are steel alloys that are designed to be highly resistant to corrosion as well.

4 Mechanical Properties

Understanding the difference between cast iron and steel in terms of mechanical properties like strength, ductility, and wear resistance is key to choosing the right material for different projects.

Strength

Steel is generally stronger than cast iron. It can withstand more force before it breaks, which makes it ideal for structures that must endure heavy loads, such as bridges and skyscrapers. Cast iron, while strong, is more brittle and can crack under heavy stress, making it better for applications where the loads are consistent and not extreme.

Ductility

Ductility refers to a material’s ability to deform under stress without breaking. Steel is much more ductile than cast iron. This flexibility allows steel to bend slightly under loads, which is a crucial property for buildings and infrastructure in earthquake-prone areas. Cast iron does not handle bending well and can break suddenly if bent too far.

Wear Resistance

Cast iron typically has better wear resistance than steel, especially in conditions where there is a lot of friction. This makes it a popular choice for machine parts like gears and pistons that move against each other.

Environmental Suitability

- Cast Iron: Performs well in outdoor settings due to its resistance to rust and corrosion when properly treated. It’s often used in outdoor furniture, fences, and cookware.

- Steel: Needs protective coatings to resist corrosion, especially in humid or marine environments. However, certain steel alloys are designed to be exceptionally resistant to harsh conditions.

5 Common Applications

When choosing between cast iron vs steel, understanding their common applications in various industries is helpful. Here are some specific uses and examples of products made from each material, highlighting the cast iron and steel difference.

Cast Iron

- Cookware: Cast iron is famous for its excellent heat retention and distribution, making it ideal for skillets, pans, and Dutch ovens.

- Automotive Components: Due to its high wear resistance, cast iron is commonly used in brake rotors and cylinder blocks in cars.

- Pipes and Manhole Covers: Its ability to withstand heavy loads and resistance to degradation makes cast iron a good choice for outdoor and underground infrastructure.

Cast Steel

- Construction: Steel’s strength and ductility make it perfect for structural components such as beams, columns, and reinforcing bars in buildings and bridges.

- Tools and Machinery: High-strength steel is used in making tools, blades, and heavy machinery that require durability and the ability to withstand forceful impacts.

- Transportation: Components like steel rails and ship hulls benefit from steel’s toughness and flexibility, ensuring safety and longevity in demanding environments.

Understanding these applications shows why the difference between cast iron and steel is significant and how each material serves specific purposes across different sectors. This knowledge can guide decisions in material selection for various projects, ensuring optimal performance and cost-effectiveness.

6 Cost Considerations

Advantages of Cast Steel

When it comes to the difference between cast iron and steel in terms of cost, several factors influence why one material might be chosen over the other based on budget constraints.

Cast Iron

- Lower Cost: Generally, cast iron is cheaper to produce than steel. This is due to its simpler production process and the lower cost of the raw materials involved.

- Cost-Effective for Large Quantities: When producing items in large quantities, such as pipes or cookware, cast iron often remains cost-effective because it can be cast into shapes relatively easily and quickly.

- Durability: Although cheaper, cast iron is durable for certain applications, making it a worthwhile investment for products like heavy-duty cookware and municipal covers that do not require high ductility.

Cast Steel

- Higher Production Costs: Steel typically costs more due to its more complex production process, which often includes additional steps like forging and treating to enhance properties like strength and ductility.

- Long-Term Savings: Despite its higher initial cost, steel can be more cost-effective in the long run for projects that require structural integrity and durability under stress, such as in the construction and automotive industries.

- Customization and Performance: Steel’s adaptability in terms of alloy composition can be tailored to meet specific needs, which, while increasing cost, provides significant performance benefits that justify the expense in critical applications.

7 Advantages and Disadvantages

When considering cast iron vs steel, each material has specific strengths and weaknesses that make it suitable for different applications. Here’s a straightforward look at the pros and cons of each:

Cast Iron

Advantages:

- Good Wear Resistance: Cast iron excels in situations where surfaces rub against each other, making it ideal for machine parts like gears and automotive brakes.

- Excellent Heat Retention: This property makes cast iron popular for cookware that needs to maintain consistent temperatures.

- Cost-Effective Production: Generally cheaper to produce than steel, cast iron is favourable for bulk manufacturing of durable items.

- Vibration Damping: Cast iron naturally absorbs and dampens vibrations, which is beneficial for machinery and engine parts.

Disadvantages:

- Brittleness: Although tough, cast iron can be quite brittle compared to steel, limiting its use in applications requiring flexibility.

- Poor Tensile Strength: It tends to crack under tension, which makes it unsuitable for bending or twisting applications.

- Corrosion Susceptibility: Without proper treatment, cast iron can rust and degrade over time, especially in harsh environments.

Cast Steel

Advantages:

- High Strength: Steel provides superior strength and durability, which is essential for structural and load-bearing applications.

- Flexibility and Ductility: Steel can be deformed before breaking, making it suitable for high-impact environments like construction sites prone to earthquakes.

- Customizable Alloys: The composition of steel can be adjusted to enhance certain properties like corrosion resistance or hardness, making it versatile for a wide range of applications.

- Better Tensile Strength: Steel withstands tension and pressure better, making it ideal for cables, wires, and structural supports.

Disadvantages:

- Higher Cost: Steel’s production is more resource-intensive, leading to higher costs, especially for custom or alloyed varieties.

- Maintenance Needs: Depending on the environment, steel may require treatments to prevent corrosion, adding to its overall maintenance cost.

- Energy Intensive Manufacturing: Producing steel, particularly in forms like stainless steel, requires significant energy and technological input.

8 Case Studies

Understanding the practical applications of cast iron vs steel can be best achieved through real-world examples. Here are a couple of case studies that show how these materials are chosen based on their properties and project requirements:

Automotive Industry - Brake Discs

Material Used: Cast Iron

Reason for Choice: Cast iron is traditionally used for brake discs in cars due to its excellent heat resistance and ability to withstand wear. The ability of cast iron to absorb and dissipate heat helps in managing the high temperatures generated during braking, which enhances performance and longevity.

Outcome: Despite the weight, cast iron’s cost-effectiveness and performance under high-friction conditions have kept it as a preferred choice for standard passenger vehicles. However, for high-performance or racing vehicles where weight reduction is critical, manufacturers often opt for steel or composite materials.

Construction Industry - Structural Framework

Material Used: Steel

Reason for Choice: For the construction of a new high-rise building, steel was chosen for the structural framework due to its high tensile strength and ductility. These properties are crucial in skyscraper construction, where the building must withstand not only vertical loads but also lateral pressures from wind and seismic activities.

Outcome: The use of steel allowed for a taller, more flexible structure capable of enduring environmental stresses. It also facilitated faster construction due to steel’s suitability for prefabrication.

Municipal Infrastructure - Sewer Pipes

Material Used: Cast Iron

Reason for Choice: Cast iron was selected for sewer pipes in a large city’s infrastructure project due to its durability, corrosion resistance, and ability to bear large loads from underground installation.

Outcome: The cast iron pipes provided a long-lasting solution that could withstand the harsh underground environment and heavy urban traffic loads. The decision was influenced by the material’s longevity and low maintenance needs despite the potential for corrosion over time.

9 Wrapping Up

In this blog, we looked at the main differences between cast iron and steel, including their history, how they may be made, and their properties. Cast iron is less expensive and exceptional for things like pots and city infrastructure as it retains heat well and wears down slowly. Steel is more potent and flexible, making it a good choice for constructing skyscrapers and for use in transportation, although its prices are higher. When choosing between cast iron and steel, think about the requirements of your project, how much can you spend, and the way these materials affect the environment. Understanding these differences allows you to choose the proper material for fine stability of overall performance, cost, and environmental impact for your needs.

FAQs about Cast Iron VS Steel

Is cast iron more expensive than steel?

No. Cast iron is, in fact, a lot cheaper than cast steel. This is because cast iron is easily accessible, and it requires lower material costs, energy and labour to produce the final product. Raw steel is more expensive than cast iron because it is harder to cast.

What are the disadvantages of cast iron?

Cast iron products are heavy, and they are not good at retaining heat. Also, it has a low melting point and, thus, does not provide enough flexibility. Cast iron cookware also cracks easily.

Can cast iron rust?

Cast iron products, with a protective layer of carbonised oil, do not rust easily. Also, such products need a lot of tending. It is not advisable to keep cast iron products in water or high temperature for a long time. This can welcome early rust even if your product is fairly new.

Is it healthy to cook in cast iron?

For many generations, cast iron utensils were used to cook food on daily basis. Cast iron cookware is a healthier and safer alternative to non-stick cookware. However, it is necessary to know that it is advisable not to cook food in such cookware on high heat. Keep the heat on low to medium while cooking. This way, the cookware won’t break and mix brittles with the food.

Does cast iron crack easily?

It is true that cast iron has brittle mechanical properties. But it is also heavy and tough. So, it does not break easily if you take exceptional care of the cast iron things. For extra safety, keep these products away from kids, cook food in cast iron utensils on low to medium heat and do not keep them in water for a long time to soak.

Community Q&A

About This Article

Hardik Jethva is an experienced author of the BestCheck family. Working from scratch, he has developed an amazing interest in testing and writing about different products in a transparent manner. His writing skills got more audience for BestCheck. Apart from his professional life, Hardik has his eyes on travelling, meditation, eating healthy food, socializing with people, and car rides.

This article has been viewed 1235 times.